Optimal Timing for Epoxy Flooring

Epoxy flooring installation is highly dependent on environmental conditions. Proper timing ensures optimal adhesion, curing, and durability of the coating. Typically, the best time for epoxy floorings is during periods of stable, moderate temperatures and low humidity, which facilitate proper curing and adhesion.

Epoxy coatings perform best when ambient temperatures are between 60°F and 85°F. Extremes outside this range can compromise the curing process.

Low humidity levels prevent moisture-related issues such as bubbling or improper curing, ensuring a smooth, long-lasting finish.

Spring and early fall often provide optimal conditions for epoxy installation, avoiding the extreme cold of winter or heat of summer.

Timing also involves ensuring the surface is free of moisture and debris, which is easier during dry, mild weather.

Spring’s moderate temperatures and low humidity create ideal conditions for epoxy flooring projects.

Summer’s warm weather accelerates curing, but high humidity must be managed for best results.

Early fall offers cool, dry conditions suitable for epoxy application before winter sets in.

Ways to make Epoxy Floorings work in tight or awkward layouts.

Popular materials for Epoxy Floorings and why they hold up over time.

Simple add-ons that improve Epoxy Floorings without blowing the budget.

Epoxy flooring provides a durable, seamless surface ideal for garages, commercial spaces, and industrial settings. Its resistance to chemicals, stains, and wear makes it a popular choice for high-traffic areas. Proper installation and timing are crucial to maximize lifespan and performance. Temperature and humidity levels significantly influence the curing process, affecting adhesion and finish quality. Statistics indicate that epoxy floors can last over a decade with proper maintenance, offering a cost-effective flooring solution over time.

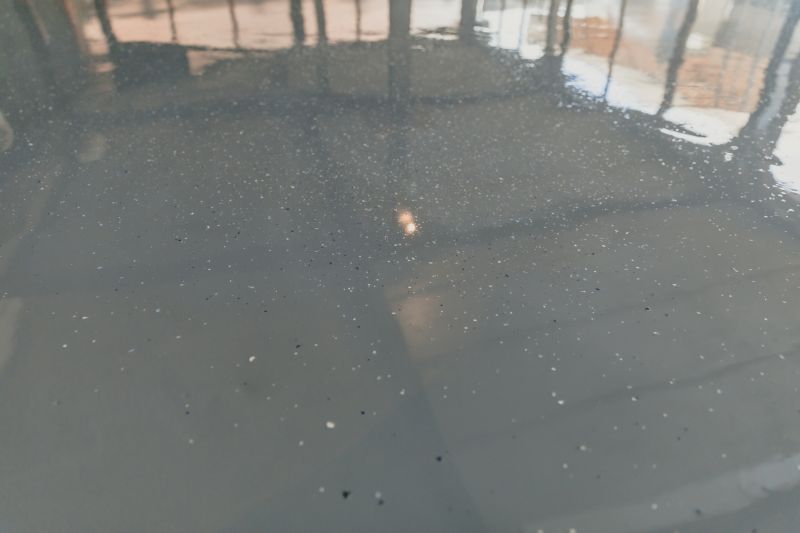

A smooth, glossy epoxy surface demonstrating high durability.

Epoxy floors in a warehouse environment with high traffic.

A modern garage with a sleek epoxy finish.

A retail or commercial area featuring epoxy flooring.

High-end options that actually feel worth it for Epoxy Floorings.

Finishes and colors that play nicely with Epoxy Floorings.

Little measurements that prevent headaches on Epoxy Floorings day.

A 60-second routine that keeps Epoxy Floorings looking new.

A frequent mistake in Epoxy Floorings and how to dodge it.

Small tweaks to make Epoxy Floorings safer and easier to use.

Lower-waste or water-saving choices for Epoxy Floorings.

The short, realistic tool list for quality Epoxy Floorings.

| Condition | Optimal Timing |

|---|---|

| Temperature | 60°F - 85°F |

| Humidity | Below 70% |

| Season | Spring and early fall |

| Weather Stability | Clear, dry days |

| Surface Readiness | Surface dry and free of moisture |

| Project Duration | Plan during moderate weather periods |

| Temperature Fluctuations | Avoid extreme cold or heat |

| Rain Risk | Minimize rain exposure before curing |

Choosing the right time for epoxy flooring installation enhances performance and longevity. Proper environmental conditions allow for optimal curing, adhesion, and appearance. Planning projects around favorable weather conditions reduces the risk of defects and ensures a seamless, durable finish. If interested in scheduling an epoxy flooring installation, contact for more information and assistance.